Andrew Waugh (AW): Maggie’s is a beautiful building and certainly informed our work on MultiPly. Our ambition now is to push the material to the next stage, hand in hand with modular and prefabricated construction, which we’ve long been interested in and committed to as a practice.

Mike Jeffree (MJ): Waugh Thistleton has completed 20 CLT projects and in Murray Grove Tower, also in CLT, were designers of the world’s first tall residential building. When and why were you first attracted to construction in timber, and CLT in particular?

AW: My partner Anthony Thistleton and I designed our first CLT building in 2003, and we became fascinated with it straight away. We were increasingly interested in sustainability and found the idea of not building in steel and concrete really attractive. It was also an issue of control. As an architect, you’re often frustrated using these conventional materials that what you draw is not what is built – particularly in concrete, which is a very imprecise medium. The idea of having a building prefabricated in quality-controlled factory conditions exactly to our drawings, and comprising a replenishable material made of carbon that would then arrive on site in panels to be simply screwed together with cordless screwdrivers got us both very excited!

MJ: What shaped or inspired the particular way you use CLT in your buildings?

AW: There was no real tradition of using CLT in the UK and, unlike some counterparts in Europe, we had no support or encouragement from government, or indeed clients – of the 20 CLT buildings we’ve designed, just two instructed them in timber, the other 18 we persuaded to use it! Against that background we had to learn how to use the material very efficiently. It was a Nissan Leaf rather than a Tesla approach, but we now feel we have an affordable, efficient, accessible and beautiful solution to the environmental impact wrought by concrete and steel.

MJ: You’re approach is clearly now attracting a growing building sector audience. You’ve worked on their timber building systems with Swan Housing, Vastint and L&G. What’s the increasing appeal?

AW: Perhaps it’s the fact that the onus in architecture and construction is more and more to go beyond just meeting the client’s brief. Our actions impact on the community at large, so we must understand the context buildings sit in. That process today also increasingly has to take into account questions of climate change and the environment. If it doesn’t, architects simply aren’t doing their job. Politicians are going to turn around shortly and to their amazement find people increasingly worried and concerned about these issues. A vast amount of greenhouse gases also come from concrete and steel, while construction using them exclusively is a wasteful, drawn out process. Moreover we have a housing crisis for which no one is coming up with sensible answers. But in prefabricated modular timber construction you have a solution to both these things, environmental impact and the housing shortage. And it delivers better housing.

AHEC/MJ: Over time, Waugh Thistleton has also employed a growing range of engineered timber products; hardwood and softwood laminated veneer lumbers, glulam and strandboard, plus softwood and hardwood/softwood-blend CLT's. So what does wholly hardwood CLT bring to the table?

AW: AHEC approached us and said here’s this material which is still really in its infancy and we’d like you to explore what it can do. Tulipwood is both a beautiful timber and as a hardwood its strength to weight is greater than spruce, which is commonly used for CLT, meaning you can do more with less. That said, we don’t view hardwood CLT as a competitor to softwood. We see building in wood as increasingly about blending these various materials. Sometimes softwood CLT will be more suitable, perhaps for acoustic or thermal insulating considerations, sometimes hardwood will be more appropriate where you need to use lower volumes, as with MultiPly. The aim is to expand our palette of timber building products and increase their capacity to compete with other materials.

MJ: AHEC has developed a range of tools to validate American hardwoods’ environmental credentials, such as its American Hardwood Environmental Profile detailing a hardwood shipment’s carbon and wider environmental impacts, and the sustainability calculator, which shows how long it takes to regrow a specified volume of a particular species. As an architect, do you find these helpful?

AW: Naturally! The environmental impacts of all construction materials are increasingly important considerations in their choice and AHEC’s messaging is factual and engaging – a shining example of how to project this industry and building with timber.

MJ: You’ve canvassed the views of people living in your timber buildings, what has been the feedback?

AW: We’re now doing a major post occupancy evaluation with Barclay Homes and Sheffield University, but other feedback has been very positive. I often do a talk outside Murray Grove and residents helpfully shout down from their balconies comments like “I’ve never heard my neighbours” and “I never need to use the heating!" And I also live in a CLT house. As it has no thermal mass it’s comfortably warm in the day, cool at night. I love it.

MJ: Have there been benefits in having the CLT panels made at CSIC rather an established continental CLT producer?

AW: It’s enabled us and Arup to work with them to refine the panels for the project. And we’re also keen to encourage UK manufacture of CLT and other engineered wood products. It could help develop the market and, while AHEC has shown that U.S. hardwood lumber remains carbon negative, despite shipping it over the Atlantic, having the end product made here could further enhance its environmental footprint.

MJ: AL_A Architects’ £54 million remodelling of the Sackler Courtyard means that MultiPly effectively sits on the roof of the new subterranean gallery space below. Did that put special demands on the project?

AW: It meant working closely with Arup on the weight distribution, but also having a structure that was relatively light weight in the first instance and strong, as we have no foundations. So tulipwood CLT’s specific properties were paramount in this context.

MJ: Will you have to closely control the number of people exploring MultiPly at any one time?

AW: Well it’s an extremely robust material and structure – so the limit on the number of visitors will be how many fit, rather than the weight!

MJ: What other impacts do you think MultiPly will have?

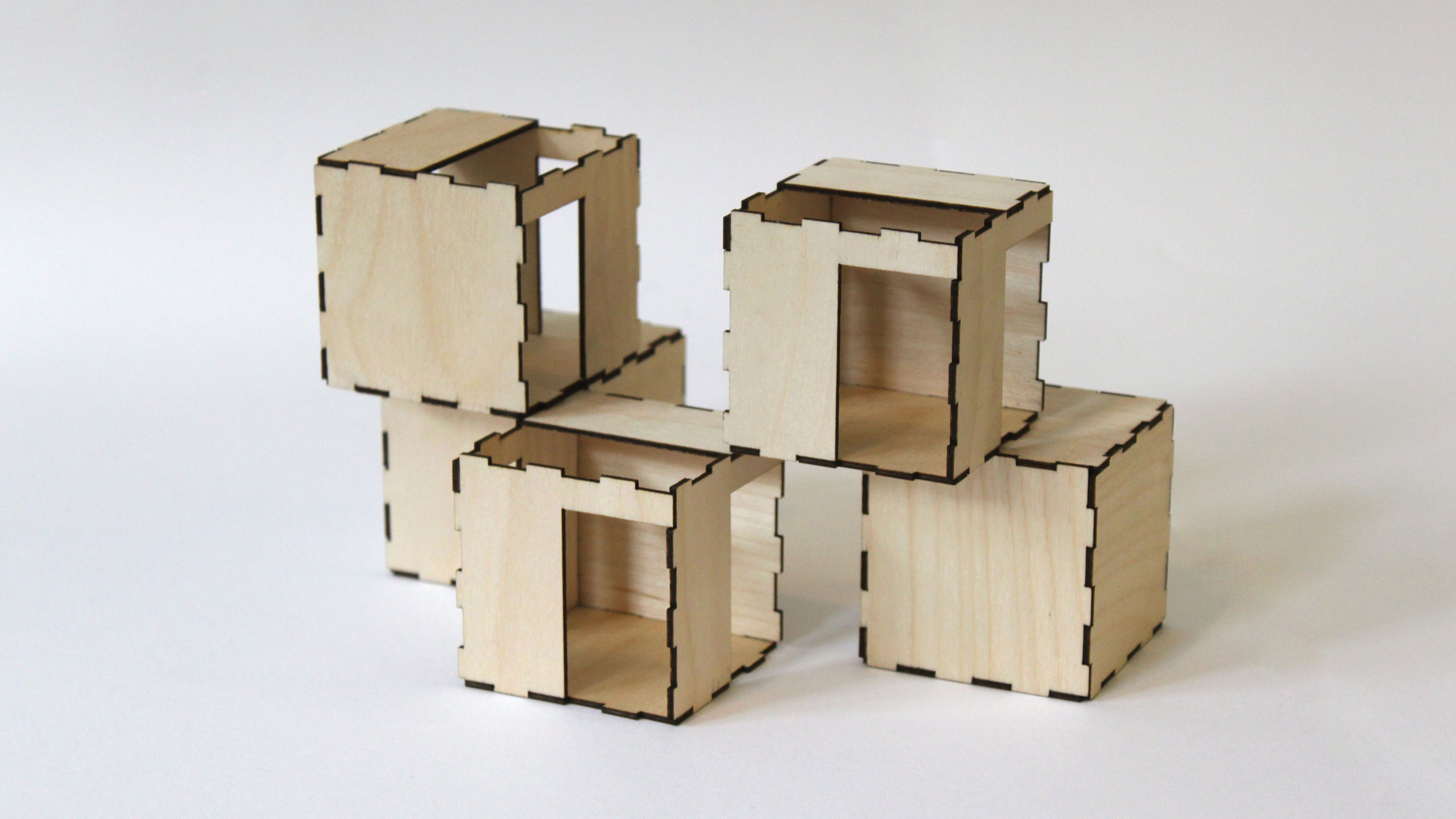

AW: It will highlight the speed and accuracy of of modular construction. The joints are digitally manufactured to ensure they fit precisely and for added simplicity there are just two steel construction details – so it will take less than a week to build.

It will also challenge popular preconceptions about the aesthetics of prefabricated building, while retaining its essential attributes. It doesn’t look modular – that popular perception of the same old prefab box. It’s very specific to context in weight, form and height. But then, after the Festival we’ll be able dismantle it and rebuild it in a different form somewhere else.