Material

The entire lifecycle of the Cove lounge from the US to what you see here today has been analysed.

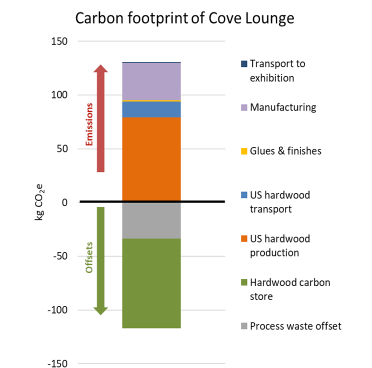

The carbon footprint is 18.7 kgCO2equivalent

That's about the same carbon emitted in a single 125km journey in the average Australian car* (125km).

The American red oak used to create this design arrived on Australian shores carbon negative.

This analysis applies despite this assessment accounting for a very long and tortuous transport route including 1,100 km by truck from lumber processing location to the East Coast of the US, and shipment via Suez and Singapore to Sydney, a total distance by container ship of 26,000 km.

The total emissions resulting from the creation of COVE are 135.7 kgCO2e. This includes ALL processes from material extraction, through transport of materials, manufacturing, and delivery of finished product to the exhibition. These are offset by 83.6 kgCO2e of carbon stored in the finished furniture and 33.5 kgCO2e due to burning of wood offcuts/waste (which reduces inputs of fossil fuels into other processes).

The small steel plates used as part of the manufacturing process alone contribute 5.5 kgCO2e to the design.

Another important determinant of carbon footprint for wood products is the sustainability of harvesting. Crediting carbon storage in wood is only legitimate if it is known to derive from a sustainable forest resource. This is true of red oak - there are 2.6 billion cubic meters of red oak standing US forests and harvest levels of around 32 million cubic meters per year are well below growth (net of natural mortality) of around 60 million cubic meters per year. It takes just a small fraction of a second (0.14 seconds) for the red oak used for the design to be replaced by regrowth in the US hardwood forest.

*Based on data from the FCAI's voluntary emissions standard which shows that the 2020 average emissions intensity for passenger cars and light SUVs was 149.5 g/km.