Making

The Endless Stair was much more than just a piece of art: it pioneered the use of hardwood in CLT. A fast-establishing technology, CLT is usually made from softwood, but AHEC believes that there is real potential for using tulipwood, a sustainably abundant, relatively inexpensive and structurally impressive American hardwood.

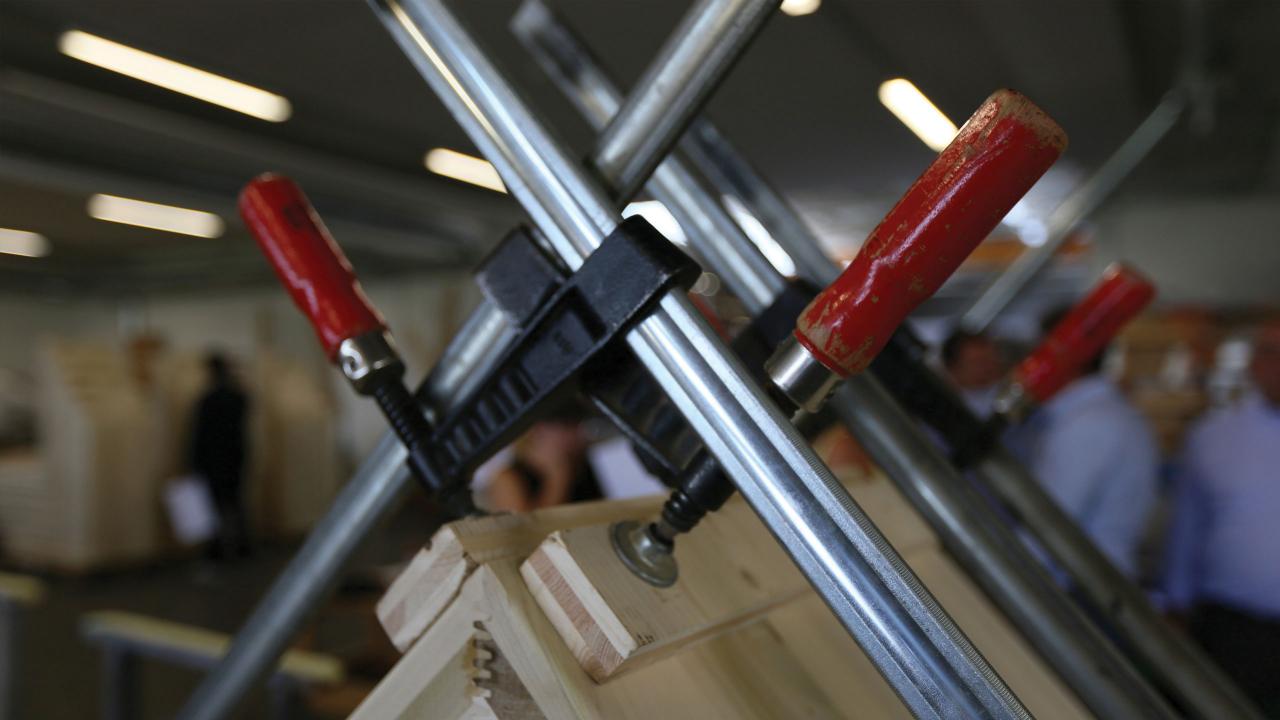

To test this idea AHEC worked on the Endless Stair with architect dRMM and engineer Arup, to create a design that was not only visually exciting but that also tested the potential of this new form of timber. Manufacturers in Italy and Switzerland made the elements, which were assembled quickly and efficiently on site.

CLT is an engineered timber product that is used increasingly to create the walls and floors of buildings. It is of a ‘sandwich’ construction, normally with an odd number of layers in the sandwich. On each successive layer the fibres of the timbers run in opposing perpendicular directions, so that if you could look through the CLT from above you would see a kind of grid of fibres. It is orthotropic – that is, it has different properties in three directions. This is important because timber is strong along the directions of the fibres, and less so in the cross direction. Modern offsite manufacturing methods mean that CLT panels can be made in a factory and then delivered to site for assembly in a fast, rapid and accurate manner, cutting down on the time needed for construction and the risk involved.

By assembling the material in layers the structural impact of individual pieces is averaged out across the panel, ensuring better control of material properties and also allowing lower quality material to be used that would otherwise be unsuitable for this kind of structural joinery. The use of No 2 Common grade (NHLA visual grading standard) tulipwood resulted in a 40% saving in cost compared to the FAS grade normally used for joinery applications.

The manufacturers of CLT panels, most of which are based in northern Europe, use softwood – most commonly spruce. The question that AHEC posed was, would it be feasible to use a stronger hardwood to make the panels?

Solid CLT panels have inherent fire resistance and therefore can be left exposed in finished structures without applied fire protection. Hardwood CLT therefore offers the benefits of a fire resistant material combined with the visual appearance and inherent strength of the American tulipwood.