DESIGN PROCESS

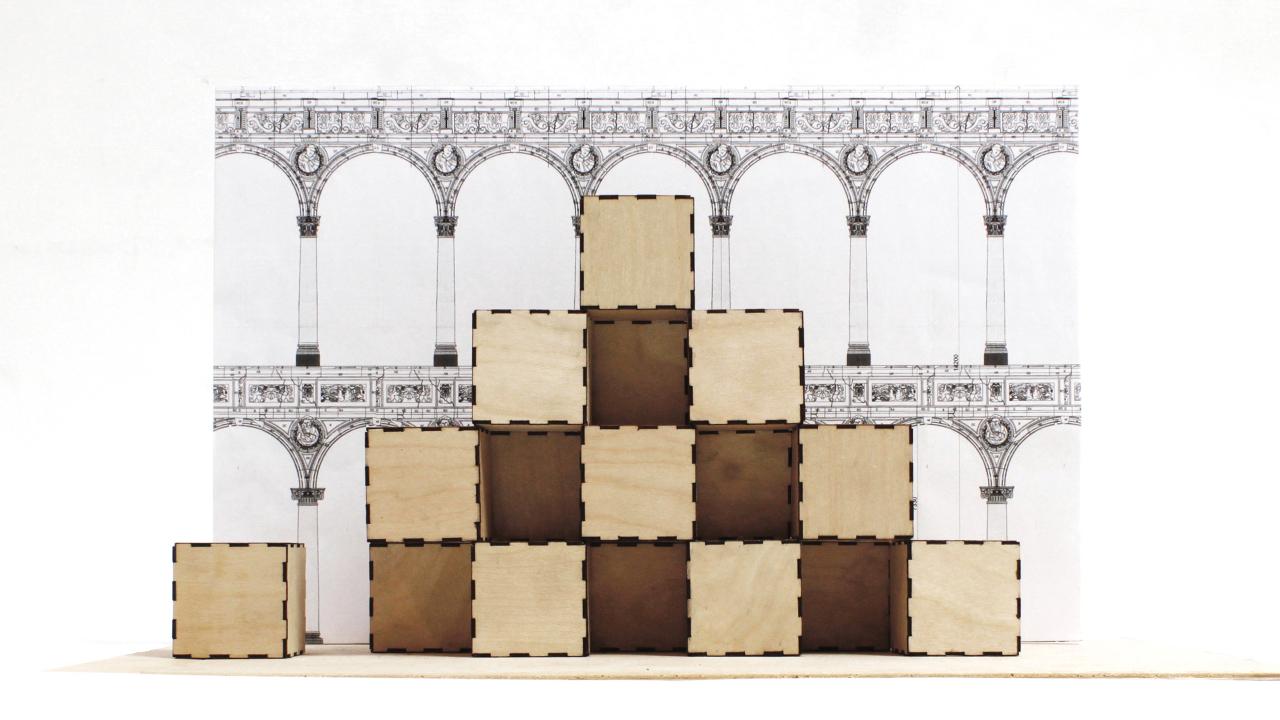

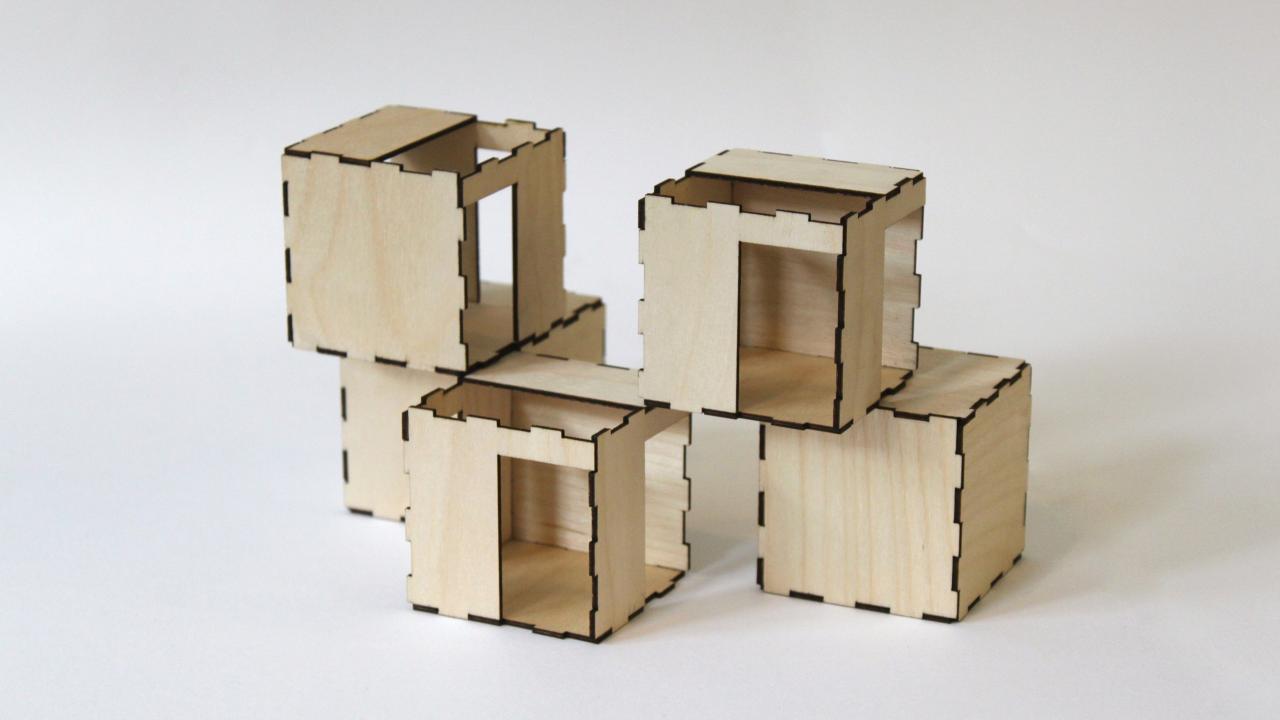

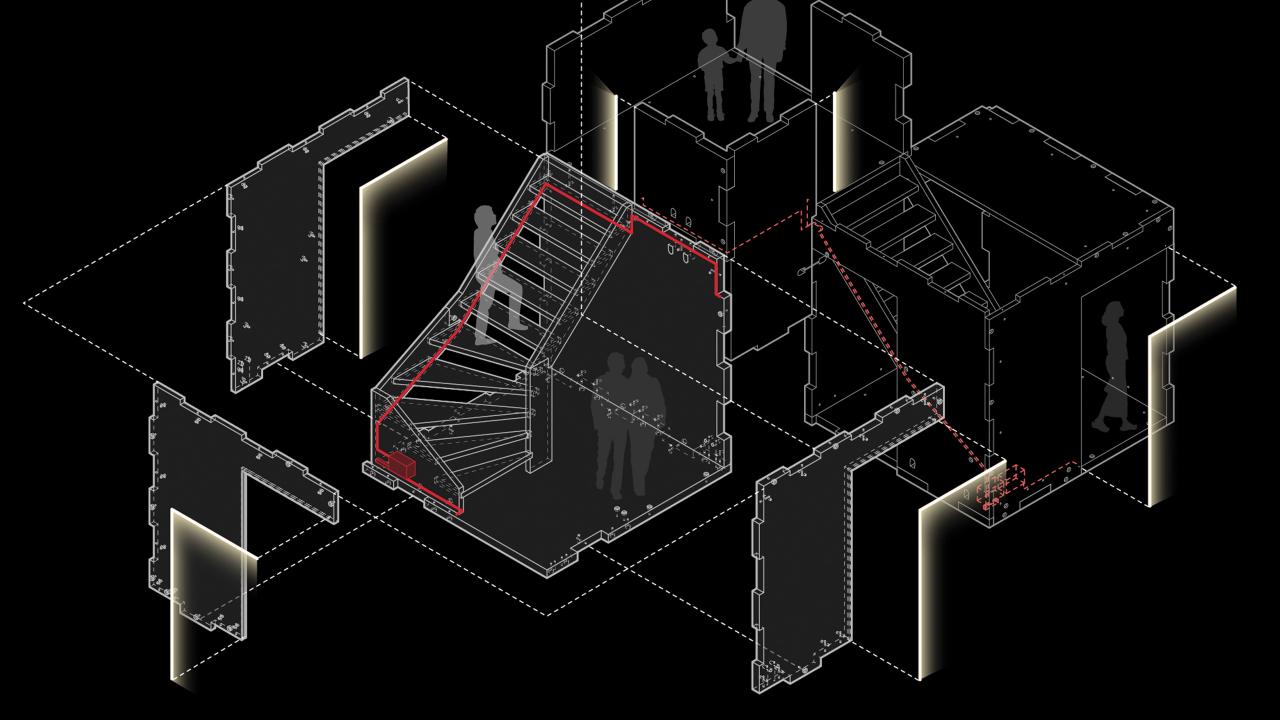

The complete structure comprises 17 interconnecting modules, made from a total of 102 60mm and 100 mm thick x 2.6m long cross laminated timber panels (CLT) finger-jointed by Glenalmond Timber and fabricated at the Construction Scotland Innovation Centre (CSIC).

Working with CSIC rather than an established continental CLT producer enabled Waugh Thistleton and Arup to have more control through each stage of the manufacturing process and refine the intricate design.

It's first location, at the remodelled Sackler Courtyard in London, is the roof to the subterranean gallery below and has no foundations adding a unique demand to the project. The lightweight property of tulipwood CLT lent itself perfectly to the space and meant Waugh Thistleton could go even scale the structure up to 9 metres tall.

Carolina Bartram, Project Director, Arup commented, “The seemingly simple series of stacked boxes are a complex engineering challenge, made more interesting by the fact the sculpture sits on the newly completed, elegant Sackler Courtyard at the V&A. It is a privilege that as engineers for the Sackler Courtyard, we are also contributing engineering designs for MultiPly.”

Highlighting the potential for the speed of construction of the modules was paramount. All of the joints have been digitally manufactured by Stage One with great precision and, to make the design even more streamlined, there are only two steel construction details. These clever design details means the structure can be assembled in under a week.

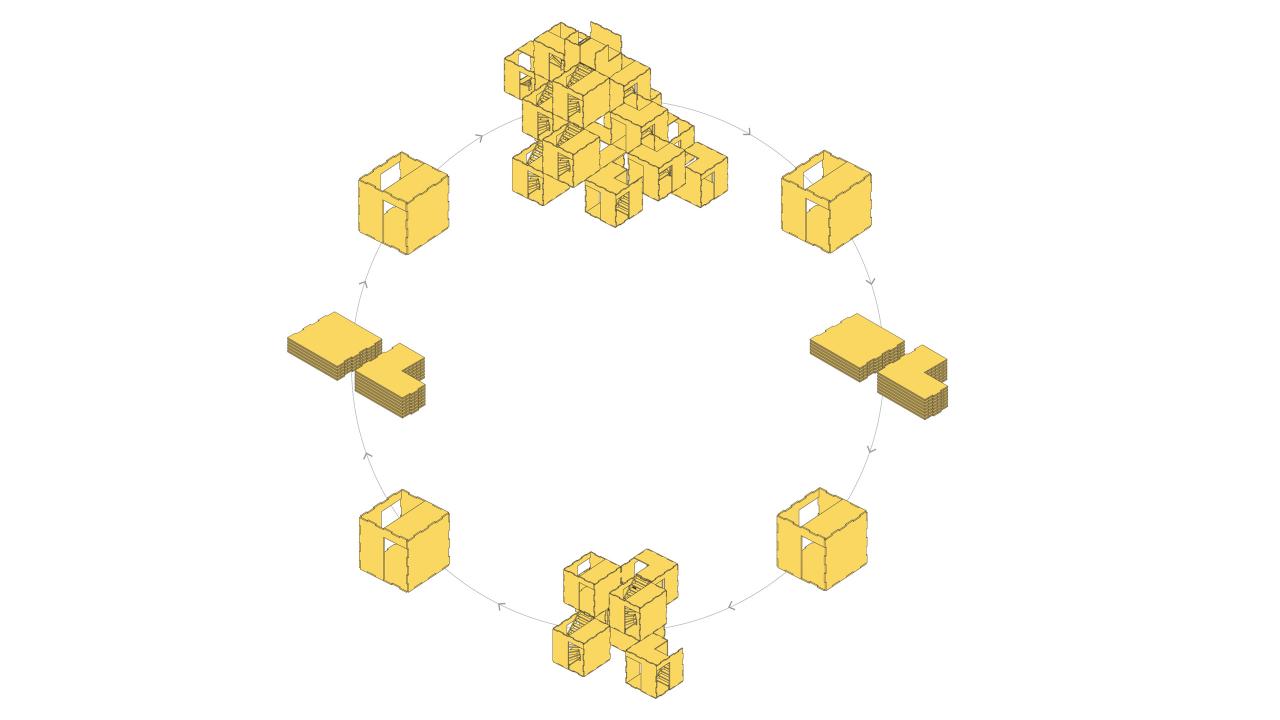

It's flexible design meant that following the London Design Festival, six of the original modules were relocated to a temporary home in South Crescent on London’s Store Street as part of a collaboration with New London Architecture.

A set of benches and tables, made with thermally-modified American tulipwood were also placed around the pavilion. This timber has been modified by controlled heating, effectively crystallising the wood’s cambium and providing enhanced stability and durability. The process changes the appearance of the tulipwood, giving it deeper brown tones throughout and making it suitable for external applications.

It's third location see's the pavilion travelling across the sea to Milan for Inerni magazine's Human Spaces, as part of Milan Design Week. Its new inception in Italy shows how easily it can be reconfigured to meet the users’ needs.

“Bringing MultiPly to Milan in a new configuration brought with it new challenges,” says Simon Bateman, Structural Engineer at ARUP. “We were building higher than we did in London, from a narrower base, and on a windier site: this meant that the first priority was checking that the structure would stay stable in the wind. We then had to thoroughly review the fixings between the boxes for the new configuration, and add new ones where necessary, which was relatively straightforward due to the modular form. "