Measurement

The NHLA lumber grading rules adopted by the US hardwood industry are based on an imperial measurement system using inches and feet. In contrast most export markets are more familiar with a metric standard. Additionally, the grade rules were developed with random width and length lumber in mind. Any selection for particular specifications should be discussed prior to ordering.

Board Foot

- A board foot (BF) is the unit of measurement for hardwood lumber.

- A board foot is 1 foot long x 1 foot wide x 1 inch thick. (1 foot = 0.305 metres, 1 inch = 25.4mm)

- The formula for determining board feet in a board is:

W (width in inches) x L (length in feet) x D (thickness in inches) ÷ 12 = BF

- The percentages of clear wood required for each grade are based on this 12’ unit of measure.

Surface Measure

Surface measure (SM) is the surface area of a board in square feet. To determine surface measure, multiply the width of the board in inches by the length of the board in feet and divide the sum by 12, rounding up or down to the nearest whole number. The percentage of clear wood required for each grade is based on the surface measure, not the board feet, and because of this all boards, no matter what the thickness, are graded in the same way.

W (width in inches) x L (length in feet) ÷ 12 = SM

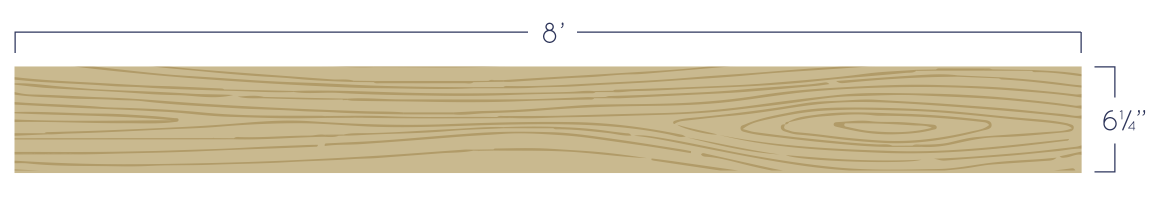

Example of SM and BF:

The board below is a 2” thick, 6 1/4” wide, and 8’ long.

6 1/4” x 8’ ÷ 12 = 4 1/6

thus the SM is 4’.

4’ x 2” = 8’

Multiply the SM by the thickness 2” and the BF is 8’.

When preparing a bundle tally for export, the boards are recorded by their width and length. Random widths above or below the half inch are rounded to the nearest whole inch. Board widths falling exactly on the half inch are alternatively rounded up or down. Lengths that fall between whole foot increments are always rounded down to the nearest whole foot.

For example a board 5 1/4” width and 8 1/2’ long is tallied 5” and 8’.

Standard Thickness for Rough Sawn Lumber

Standard thickness for rough sawn lumber is expressed in quarters of an inch. For example 1” = 4/4. The majority of US hardwood lumber production is sawn between 1” and 2”, although other thicknesses are available in more limited volumes. The standard thicknesses and their exact metric equivalent are shown below.

3/4 (3/4” = 19.0mm)

4/4 (1” = 25.4mm)

5/4 (1 1/4” = 31.8mm)

6/4 (1 1/2” = 38.1mm)

8/4 (2” = 50.8mm)

10/4 (2 1/2” = 63.5mm)

12/4 (3” = 76.2mm)

16/4 (4” = 101.6mm)

Standard Thickness for Surfaced (Planed) Lumber

When rough sawn lumber is surfaced (planed) to a finished thickness, defects such as checks, stain, and warp are not considered when establishing the grade of a board, if they can be removed in the surfacing (planing) process. The finished thickness for lumber of 1 1/2” and less can be determined by subtracting 3/16” from the nominal thickness. For lumber 1 3/4” and thicker, subtract 1/4”.

Measurment of Kiln Dried Lumber

Net tally: The actual board feet of kiln dried lumber measured after kiln drying.

Gross or green tally: The actual board feet measured before kiln drying. When kiln dried lumber is sold on this basis, the buyer can expect to receive approximately 7% less board feet because of shrinkage in the kiln drying process.

INSPECTION OF KILN DRIED LUMBER

The minimum widths and thicknesses mentioned in this publication are based on Green or Air Dried Lumber. The “Standard Kiln Dried Rule” listed in the NHLA Rules includes allowances for shrinkage after kiln drying and these are:

Rough kiln dried lumber specified 3/8” to 1 3/4” thick may be 1/16” scant of the nominal thickness; 2” and thicker may be 1/8” scant and the 10% of scant quartered lumber admitted by Paragraph 36, may be 3/32” scant on one edge in 1” to 1 1/2” lumber and 3/16” on one edge in 2” and thicker. The minimum widths mentioned in all grades may be 1/4” scant in width and the 10% admitted by Paragraph 10 may be 1/2” scant in width.

Estimating Board Feet in a Bundle of Lumber

To determine the board feet of one board, the procedure is to multiply the surface measure by the thickness. A bundle of lumber can be estimated in much the same manner. First, calculate the surface measure of one layer of boards. Do this by multiplying the width of the bundle, minus gaps, by the length of the bundle and divide the sum by 12. If there are several lengths in the bundle, use an average length. Once one layer is estimated, multiply this sum by the total number of layers.

Example:

Average width of unit 40”

(lumber only, after allowing for gaps between boards)

SM of one layer

40” x 10’ = 400 ÷ 12 = 33.33

BF of one layer (multiply SM by thickness)

33.33 x 2” = 66.66

BF of bundle (multiply by number of layers)

66.66 x 10 = 666.67

Estimated board feet of the bundle = 667BF